The advanced centralized feeding system is spe-cially for industrial recirculating aquaculture sys-tem, and marine cage culture and deep-sea aqua-culture craft. It is a positive dilute phase pneumatic conveying system, using high-speed air flow to transport feed pallet to the aquaculture pond for spreading or spraying, to realize auto-feeding at fixed time, quantity and parameters.

The system can complete settings, parameter reading, historical data acquisition and storage by selecting field or remote operation, realize un-attended automatic feeding, and meet the needs of modern industrialized marine cage culture and deep-sea aquaculture.

Inquire Now None

Product Details

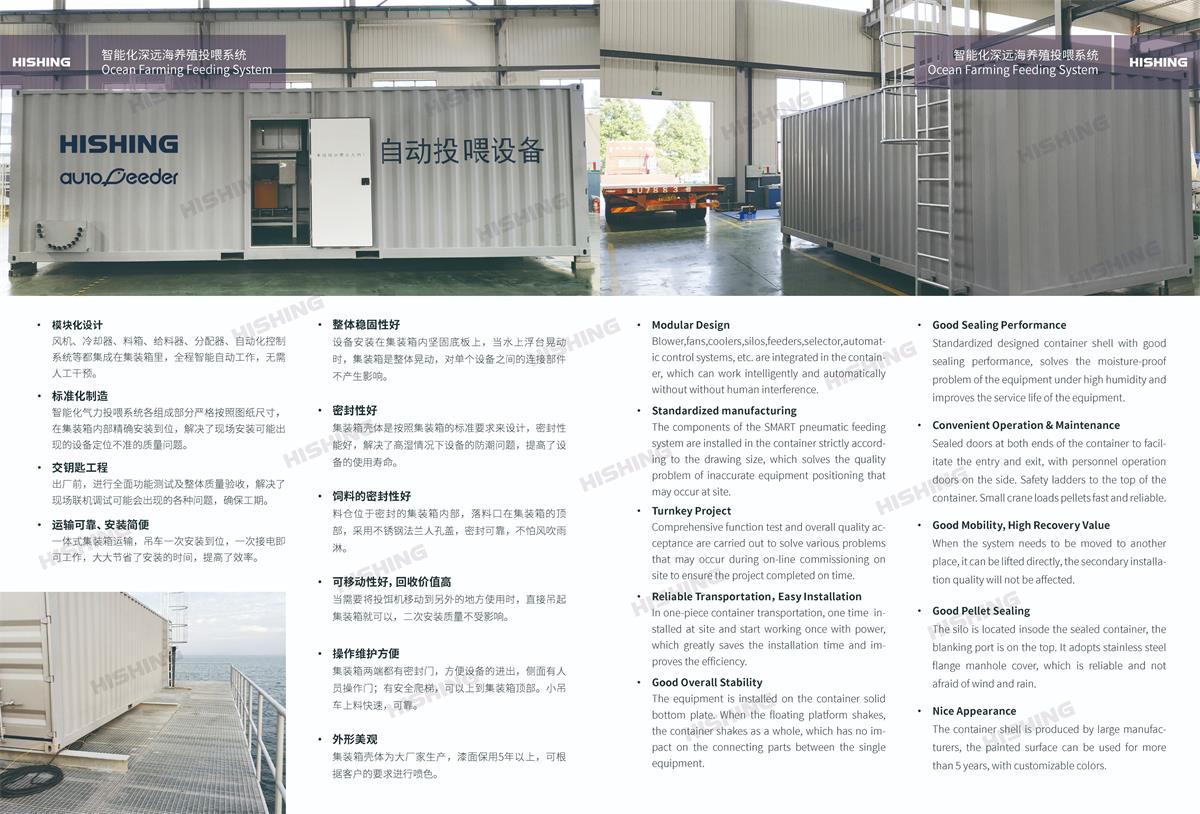

• Modular Design

Blower,fans,coolers,silos,feeders,selector,automat-ic control systems, etc. are integrated in the contain-er, which can work intelligently and automatically without without human interference.

• Standardized manufacturing

The components of the SMART pneumatic feeding system are installed in the container strictly accord-ing to the drawing size, which solves the quality problem of inaccurate equipment positioning that may occur at site.

• Turnkey Project

Comprehensive function test and overall quality ac-ceptance are carried out to solve various problems that may occur during on-line commissioning on site to ensure the project completed on time.

• Reliable Transportation,Easy Installation In one-piece container transportation, one time in-stalled at site and start working once with power, which greatly saves the installation time and im-proves the efficiency.

• Good Overall Stability

The equipment is installed on the container solid bottom plate. When the floating platform shakes, the container shakes as a whole, which has no im-pact on the connecting parts between the single equipment.

• Good Sealing Performance

Standardized designed container shell with good sealing performance, solves the moisture-proof problem of the equipment under high humidity and improves the service life of the equipment.

• Convenient Operation & Maintenance

Sealed doors at both ends of the container to facil-itate the entry and exit, with personnel operation doors on the side. Safety ladders to the top of the container. Small crane loads pellets fast and reliable.

• Good Mobility, High Recovery Value

When the system needs to be moved to another place, it can be lifted directly, the secondary installa-tion quality will not be affected.

• Good Pellet Sealing

The silo is located insode the sealed container, the blanking port is on the top. It adopts stainless steel flange manhole cover, which is reliable and not afraid of wind and rain.

• Nice Appearance

The container shell is produced by large manufac-turers, the painted surface can be used for more than 5 years, with customizable colors.